The 14 sizes of conventional roller chains are available ranging from 25 to 240 such as those in conformity with ANSI  (American National Typical Institute), and ISO (Global Organization for Standardization).

(American National Typical Institute), and ISO (Global Organization for Standardization).

The chains not only meet the requirements for your minimal tensile strength prescribed by ANSI and ISO, nevertheless they also offer the major class quality inside the globe which includes a substantial fatigue power

Ideal employs

?Standard use for driving and lifting tools.

Examples

?Driving transfer units and also other tools. For multilevel parking.

Selection of chains

For variety of a chain, see the tables of “Max. Horsepower Ratings” for normal roller chains and “Designing of Chain Transmission”. On the other hand, only for any distinctive situation of reduced velocity and much less shock, “Low-speed selection” method could also be referred to.

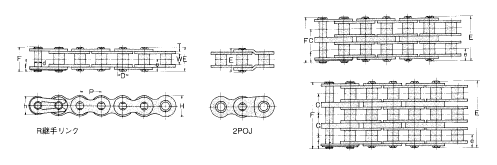

Typical roller chains up to 5 strands can be found. The standard technique for connecting pins and plates is rivet style (RP).

The cotter style (CP) is obtainable for normal chains and HK chains of 80 or more substantial.

Sprockets

The normal roller chains might be engaged with conventional sprockets on the corresponding nominal numbers. For sprockets, refer to your table of “Dimensions” for every dimension of chain.

Connecting links and offset back links

For connecting back links and offset back links, refer to the table of “Dimensions” for each dimension of chain.

The connecting back links are typically R or C connecting backlinks by which the pins are clearance-fitted with all the connecting plate. Due to the fact clearance-fitted links are RIVETLESS DROP FORGED CHAIN BAR LOOP CHAIN inferior for the base chain in Max. allowable tension as while in the situation of one-pitch offset backlinks (OJ), “Low-speed selection” cannot be referred to. Because the Max. kilowatt ratings are made a decision thinking about the power of connecting backlinks and OJ, the clearance-fitted connecting hyperlinks and OJ can be utilized when the chains are selected according to your “General selection”. Whenever a increased Max. allowable stress is needed for that connecting link, use the interference-fitted connecting link (H connecting link) of the HI-PWR-S chain, and during the situation of offset hyperlinks, use 2POJ.